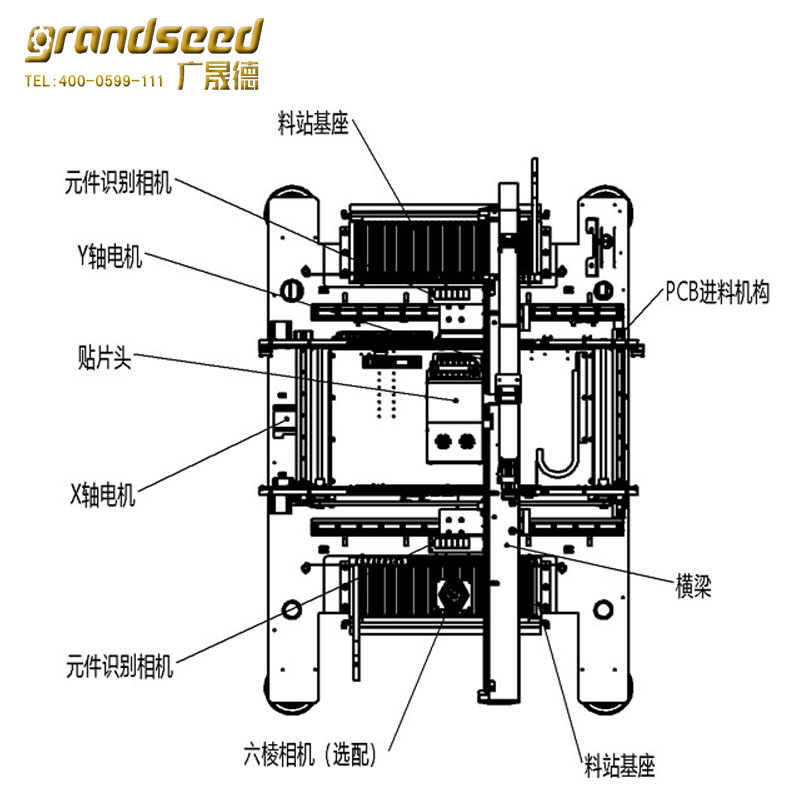

Guangshengde GSD-M306 is a high-speed and multi-function placement machine that realizes multi-function full-image mode. It can respond to small components (0402, 0603, 3216, micro transistors, etc.) at high speed and efficiently, and can meet medium and large components (SOP, QFP, etc.) , Aluminum electrolytic capacitors) range. It adopts arch structure. Linear motor. Front and rear material station. Front and rear flying camera.

0563-2251668 / 15850207552 在線咨詢Guangshengde GSD-M306 is a high-speed and multi-function placement machine that realizes multi-function full-image mode. It can respond to small components (0402, 0603, 3216, micro transistors, etc.) at high speed and efficiently, and can meet medium and large components (SOP, QFP, etc.) , Aluminum electrolytic capacitors) range. It adopts arch structure. Linear motor. Front and rear material station. Front and rear flying camera.

Application advantages of small high-speed multi-function placement machine GSD-M306

1. Use high-speed magnetic levitation motor to reduce equipment noise and improve accuracy and stability.

2. Adopting a gigabit 6-lens camera and a standard high-definition large camera to meet high-precision IC requirements.

3. Using bus control technology, high-speed placement heads can be freely replaced, and PCB board feeding methods, etc.

4. The high-precision compensation system is adopted to realize the precision compensation and correction during the mounting movement of the device.

5. Application areas: home appliances, communications, automobiles, military electronics, smart equipment and other industries.

Small high-speed multi-function placement machine GSD-M306 features and advantages

1) Using the network-type transmission of the motion photographing component recognition camera, there is no waiting or pause in the component recognition process, and it can realize the maximum speed operation in response to the small components and improve the production efficiency of the machine.

2) The operating power is 2.0-2.5kW, high-efficiency, energy-saving and electricity-saving.

3) The patch head control air circuit is installed with a bus module, which can quickly load and unload the patch head, and quickly handle and maintain the special abnormal situation to reduce time loss.

4) It adopts pneumatic and electric compatible material station base, which can be used by mixing electric and pneumatic feeders, and can be selected and used according to different materials, effectively controlling production costs.

5) The sports cable adopts a high-flexible sports cable that can be folded 50 million times, with long service life and high stability, which can greatly reduce electrical circuit abnormalities and failures.

1. Positioning method: fixed photo + mobile photo;

2. Number of shafts: 1 arm * 6 tips;

3. Mounting speed: 18000CPH;

4. Mounting accuracy: XY±0.05mm;

5. Corresponding components: 0201-30mm, 25mm> H: 15mm (optional fixed camera for materials exceeding 15mm*12mm);

6. Minimum PCB size: 50*60mm;

7. Maximum PCB size: 450*400mm;

8. PCB thickness: 0.38-4.2mm;

9. The number of feeder feeders: 8mm-64 stations (32 stations at the front and rear, with fixed cameras occupying 4 feeder stations);

10. Power supply/air pressure: AC220V/50Hz 0.5±0.7Mpa;

11. Rated power: 3.5KW;

12. Weight: 1450KG;

13. Dimensions: 1272*1280*1450mm.