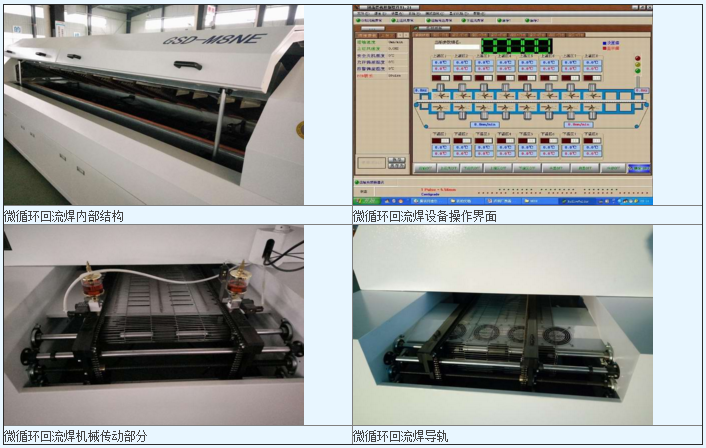

Performance characteristics of eight-temperature zone micro-circulation reflow soldering equipment Structure picture and technical parameters In order to extend the service life of the motor, our technical staff professionally designed it; the internal cooling cycle is convective, and the temperature around the motor is reduced to about 38 ℃;

0563-2251668 / 15850207552 在線咨詢Eight-temperature zone micro-circulation reflow soldering equipment GSD-M8NE structure diagram

Performance characteristics of eight-temperature zone microcirculation reflow soldering equipment GSD-M8NE

● In order to prolong the service life of the motor, our company’s technicians professionally designed it; make the internal cooling cycle convection, so that the temperature around the motor drops to about 38°C;

● The high-quality, high-temperature, high-speed motor has smooth wind, low vibration and low noise;

● Professional wind wheel design, stable wind speed, effectively prevent the uniformity of the wind when the PCB board is heated, and achieve high repeated heating;

● Each temperature zone adopts forced independent circulation, independent PID control, and independent heating methods up and down, so that the temperature of the furnace cavity is accurate and uniform, and the heat capacity is large;

● Online UPS equipped with power failure protection function to ensure the normal output of the PCB board after power failure without damage;

● Independently controlled cooling system, forced air cooling; the temperature of the PCB board after the machine is ≤50℃;

● The insulation layer is made of high-quality aluminum silicate insulation material, and the multi-layer insulation furnace design. The surface temperature of the furnace outer jacket is about 5 degrees higher than the ambient temperature, which effectively reduces the working environment temperature, has good insulation effect, and heats up quickly, from room temperature to working temperature. ≤20min; Special furnace design, low power consumption;

| project | Specification type |

| Control System | PC+PLC/Special MCU |

| Heating/cooling zone | A total of 16 heating zones / up and down full hot air micro-circulation |

| Length of heating zone | 2800mm |

| Temperature control range | Room temperature~350℃ |

| Temperature control accuracy | ±1~2 ℃ |

| Three-point temperature difference | ±2℃ |

| cooling method | Forced air cooling / 2 independent cooling zones |

| PCB size | 30~350mm |

| PCB transmission height | 900±20mm |

| Delivery method | Chain track + mesh belt conveyor |

| Transmission direction | Left → right |

| Transmission speed | 0~2000 mm /min |

| Chain track widening range | 30~350 mm |

| Transmission mesh belt width | 400 mm |

| power supply | A3?380V 50HZ |

| Normal operating power/total power | 10.8/50KW |

| Dimensions(L*W*H) | 5200mm(L)*1400mm(W)*1500mm(H) |

| net weight | 1250KG |